One of the major changes is already underway: multinational corporate executives are transferring funds and expertise to Global Capability Centres (GCCs), which are built for resilience, sustainability, and new revenue streams in addition to cost reduction. There are already more than 1,900 GCCs in India, and these centres are quickly assuming roles of engineering, R&D and sustainability on behalf of their parent organisations. This is the agglomeration of talent that makes GCCs a natural hub to operationalise circular economy models in manufacturing networks. The market of the global circular economy is developing rapidly. Corporate and regulatory pressure (such as the reinforced waste and EPR regulation by the EU) is increasing, moving towards the use of the strategies of a circle in manufacturing and supply chains. GCCs are proving to be the rational centers to develop, pilot and scale circular solutions among regions for multinational manufacturers that expand internationally.

In other words, the goal of circular economy models is to ensure that materials and products remain useful over a longer period, derive better value out of the resources and restore natural systems rather than destroying them. To produce GCCs with long-traditional engineering, product lifecycle activities and digital activities. The circular opportunity becomes tactical and strategic: cut the costs of inputs, make supply resilience and provide new services based on services (remanufacturing, refurbishment and take-back services). The result is economical and environmental.

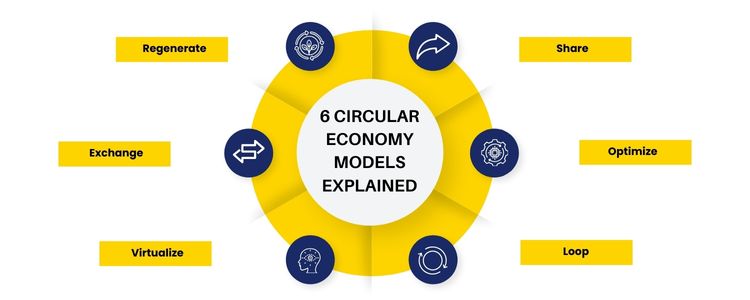

The following are the real-world models that GCC manufacturing can consider following and the abilities they need to establish. All models are naturally mapped to the prevalent GCC functions: product engineering, data analytics, supply chain orchestration, and digital platforms.

Circle strategies generate quantifiable economic results. Less utilisation of raw materials and energy directly reduces the cost of goods sold; reuse and remanufacture generate new pools of margins; design-for-reuse reduces the lead times and enhances supplier resilience. Industry studies indicate that waste stream conversion to feedstock with optimisation yields can provide cost reductions in the order of digits in selected product lines and that circular services tend to fetch greater customer lifetime value. By centralising the scale through the deployment of such capabilities, GCCs can implement similar innovations across their manufacturing footprints at a lower incremental cost.

These levers transform strategy into cost savings, readiness to comply and speedy time-to-market of sustainable products.

Efforts by regulators, like the recent increased waste directive and textile EPR schedules by the EU are compelling companies to internalise the lifecycle expenses and to take responsibility for the disposal of the products. GCCs developed to create compliance-as-a-service and supplier carbon/packaging tracking will transform regulatory requirements into competitive advantages as opposed to becoming cost centres. The increasing scope of GCCs (many of them are already heads of the global ESG and analytics functionality) makes them the key to this compliance-to-innovation shift.

The top manufacturing GCCs will have explicit circular mandates in the next five years: the ownership of product circularity KPIs, operating reverse-logistics platforms, and providing cross-border remanufacturing playbooks. Those organisations that put GCCs in charge of such roles will minimise the total lifecycle expenditure, minimise the effect of commodity shocks and access differentiated sustainable products that satisfy ever-tougher buyer and regulatory requirements.

The models of the circular economy are no longer an optional design activity anymore. They are a crucial strategic instrument that a manufacturer plans to achieve when they seek international business expansion. Global Capability Centres, with a high concentration of engineering talent and digital capability, are the only ones able to transform the circular ambition into tangible economic outcomes. The question that manufacturing leaders must address is not whether or not to go circular, but how quickly their GCCs can be organised to transform circular models into global benefit repetition.

Hyderabad, Bangalore and Pune have become significant pharma innovation centres with global delivery centres of major biotechnological and pharmaceutical firms such as Novartis, Pfizer, AstraZeneca and GSK. They offer an economic benefit of calculation, a variety of scientific and technical human resources, and speedy time-to-market. On average, businesses reduce between 25-40 percent of the operational costs and increase the rate of innovation. The next-generation operations of Pharma GCC focus on advanced molecular modelling, AI/ML-based drug discovery, cloud supercomputing, and data integration platforms, as well as quantum-ready simulations. Pharma GCCs use AI to screen molecules, predict the efficacy of drugs, optimise clinical trials and aid in making data-driven decisions, resulting in smarter, faster and safer drug pipelines. Pharma GCCs will be global innovation ecosystems that are a combination of computational chemistry, generative AI, and quantum computing. They will turn into the hubs linking data science, discovery and regulatory intelligence in the global arena. Aditi, with a strong background in forensic science and biotechnology, brings an innovative scientific perspective to her work. Her expertise spans research, analytics, and strategic advisory in consulting and GCC environments. She has published numerous research papers and articles. A versatile writer in both technical and creative domains, Aditi excels at translating complex subjects into compelling insights. Which she aligns seamlessly with consulting, advisory domain, and GCC operations. Her ability to bridge science, business, and storytelling positions her as a strategic thinker who can drive data-informed decision-making.

The Meaning of Circular in Reference to Making GCCs.

Six Circular Models

Economic Advantages

The Circular Transformative Potential Of GCCs

Round vs. GCC Capability Goal

Circular Goal

What it delivers

GCC capability required

Waste reduction

Reduced cost of inputs, increased output.

Online twins, procedure analytics.

Product life extension

New service sales, reduced replacement expenditure.

Predictive maintenance, service platforms

Resource efficiency

Reduced energy/water footprint.

Energy dashboards, IoT integration

Material recirculation

Reduced virgin material spend

Reverse logistics, material tracking.

Green innovation

Product differentiation, access to the market.

R&D, rapid prototyping, LCA

Market Signals and Regulatory Tailwinds

Future Outlook

Conclusion

frequently asked questions (FAQs)

Aditi

Hey, like this? Why not share it with a buddy?

Related Posts

Recent Blog / Post

- Pharma GCC Setup Services in India: Strategic Considerations for CXOs January 9, 2026

- Why Enterprises Are Rethinking Their GCC Strategies in 2026 January 8, 2026

- Why Most Enterprise Expansion Strategies Fall Short of Projections, And How a GCC Enabler Can Bridge the Gap January 7, 2026

- India’s GCC Ecosystem: Why the World’s Biggest Companies Are Betting Their Future on it January 3, 2026

- Healthcare GCCs in India: Where the World’s Pharmaceutical Innovation Actually Happens January 2, 2026

- Circular Economy Models and Their Relevance to Manufacturing GCCs December 30, 2025

- GCCs in Agritech: Digitizing Global Food Security December 29, 2025

- Renewable Energy GCCs: Accelerating Global Green-Tech Development December 29, 2025

- Cyber Resilience 2030: Multi-Layer Security Architecture for GCCs December 26, 2025

- Building an Integrated Risk Management Framework for Multi-Region GCCs December 26, 2025

- The Ethics of Automation: How GCCs Maintain Human Oversight in AI Workflows December 25, 2025

- Future of HR in GCCs: Data-Led, Skills-Based, and GenAI-Driven December 25, 2025

- The Proposal to Standardize India’s GCCs for Unshakeable Global Leadership December 24, 2025

- Global Capability Centers: A Strategic Growth Model for B2B Enterprises December 24, 2025

- AI Ethics & Compliance Mandates for GCC Operations in 2025 December 23, 2025