Businesses can no longer afford to make decisions that are not dynamic when it comes to complex assets. By 2024 the world digital twin market had topped the USD 25 billion mark, with analysts forecasting that by 2030 it will have rocketed to USD 156 billion, a CAGR of over 34%, as businesses invest to offer simulation, prediction, and monetization of physical systems prior to their creation. The Global Capability Centres (GCCs) of India, numbering over 1,900 nowadays, are transforming into deliberate innovation engines developing, executing, and expanding these twins of global resources. These two trends are market momentum and GCC maturation, which are the precursors of a future where digital-first modelling is the new default in capital, operations, and risk decisions.

GCCs integrate the engineering of domains, AI talent, and 24×7 scale of delivery. Such a distinctive combination enables multinational companies to centralise expertise, data engineers, OT specialists, simulation scientists and provide ongoing twin growth and maintenance. Instead of individual pilots, GCCs support industrialized, repeatable digital-twin factories that lower time-to-value and propagate international business unit best practices. The economic payoff is tangible: independent research and industry research indicate that digital twins reduce development times by up to 50 percent, reduce downtime, reduce maintenance expenses significantly, and pay back in heavy industries within 12-36 months on average. In the case of the public infrastructure, twins have the potential to enhance capital and operational efficiency by 2030 by altering the way governments and utilities rationalize the investments.

1. Energy & Utilities GCCs are constructing real-time replicas of offshore rigs, solar farms and electric grids, which examine vibration, weather, load stress, and material fatigue in real time. AI-driven twins start preemptive maintenance windows instead of waiting until something breaks, saving millions of dollars in downtime and compliance fines. This will directly prevent safety incidents for oil and gas companies and, in the case of clean energy, optimize power trading yield forecasting. 2. Automotive & Advanced Manufacturing GCCs are currently operating digital replicas on the ground of complete production facilities, such as worker movement, robotic flow, takt time, and sustainability data. This allows OEMs to experiment with different layouts in their computers and removes the expensive rework done after the assembly. In some cases, digital-first validation resulted in a 40–50% reduction and a 20% increase in throughput before production started up. 3. Smart Cities and Public Infrastructure Governments in Europe and the Middle East are now operating digital twins of metro systems, waste grids, EV charging networks and regions prone to flooding in Indian GCCs. The AI-based adaptability simulates policies, traffic behaviours, and even the crowd management in festivals. This shifts decision-making to predictive, rather than reactive, governance to make smarter allocations of funds and prevent multimillion-dollar miscalculations of infrastructure. 4. Pharma and Life Sciences Clinical Trials. In order to replicate drug behaviour in their challenging blind trial cohorts by age, ethnicity, immunity history, and comorbidity patterns, GCCs have resorted to creating synthetic population twins. This reduces the rate of trial attrition, regulatory review time, and redesign cycles significantly. The most significant effect of digital twin modelling has reduced time-to-FDA submission by 20-30 per cent when implemented at the initiation stage. 5. Aerospace/High-risk Systems Fail Virtually In the case of aviation, defence and space technology, every failure will cost millions of lives. GCC innovation centres are creating high-fidelity behavioural twins (simulating extreme conditions, such as thermal stress, missile trajectory deviations, friction heat, and turbulence testing) and attempt physical prototypes only after simulation. This takes the risk out of reality and puts it into secure digital playbooks, enabling them to certify faster, evolve designs more safely and test at a reduced cost of up to 60%.

Organisation Of Twin Delivery In A GCC Innovation Centre. This is an industrialised run of this lifecycle within GCCs and transforms one-off experiments into enterprise-class capability.

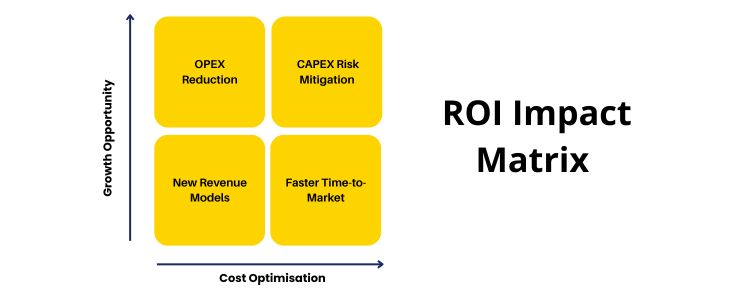

By concentrating specialised skills, cloud credits, data platform investments, and IP-reuse centralisation yields, GCCs lower the marginal cost to produce twins: 1. Epic CAPEX Risk Reduction Pre-Physical Construction. Digital twins enable businesses to test the layout, efficiency, failure modes and ROI of their plants before a single dollar is invested in actual physical infrastructure. This saves misallocation of CAPEX by 20-35 per cent and avoids sunk-cost regret, which often manifests only after deployment. 2. Maintenance Cuts Operation Losses. Businesses that have live digital twins may anticipate asset failure weeks in advance rather than reacting to it. It leads to a total OPEX savings of 5-8 per cent and millions of dollars of downtime cost savings in heavy industries. 3. Speedy Time-to-Market and Payback GTM. Enterprises can digitally simulate product performance, customer behaviour and supply chain movement to generate a 30-50% faster innovation cycle, a direct consequence of which is faster monetisation and revenue capture. 4. Reusability of Asset Templates When a digital twin architecture is developed for a single factory, refinery, port or hospital, the identical template can be copied across all markets with only minor incremental cost changes, resulting in exponential cost amortisation. 5. Change of Cost Centre into a Profit Centre. Twins are no longer merely efficiency tools within the company; they are monetised (as a digital IP) and advisory products and licensable simulation platforms. Projects of new revenue streams greater than 15-20 per cent of overall business worth have been a projection of analysts on the earliest movers in energy, manufacturing and mobility.

Over the next three years GCC Innovation centres will transfer twins out of what-if laboratories and into live decision authorities: autonomous twin agents will feed boardroom dashboards, finance models, and insurable metrics; compliance-conscious twins will reduce regulatory approvals; and product teams will be using twins as revenue-generating digital products. The victors will be those GCCs that industrialize twin IP and invest in hybrid modelling skills and governance of data, security, and monetization. Conclusion In case your capital plans are only initiated with an engineering visit to the site and a spreadsheet, rephrase the initial question: What does the twin tell us? Assign a pilot of GCC-led with quantifiable KPIs: downtime reduction, CAPEX variance, and payback months and scale with reusable twin templates. According to market and educational indications, the payoff available is high and increasing at a rapid pace; GCCs are in a unique position to transform simulation-based insight into competitive advantage.

A GCC is an offshore facility of a multinational company that undertakes niche roles such as research and development, information technology service and strategic management. It is a government program that gives the women entrepreneurs up to 1 crore in bank loans to fund greenfield projects. Personal responsibilities and unconscious bias are the factors that lead to their mid-career attrition and slow them down in their careers. They introduce new ideas, understanding, and team-oriented leadership that speeds up the advancement of such areas as AI and cybersecurity. By 2030, women are expected to take up 25-30 per cent of GCC leadership positions, which will be paramount to the growth of the Indian market. Aditi, with a strong background in forensic science and biotechnology, brings an innovative scientific perspective to her work. Her expertise spans research, analytics, and strategic advisory in consulting and GCC environments. She has published numerous research papers and articles. A versatile writer in both technical and creative domains, Aditi excels at translating complex subjects into compelling insights. Which she aligns seamlessly with consulting, advisory domain, and GCC operations. Her ability to bridge science, business, and storytelling positions her as a strategic thinker who can drive data-informed decision-making.

Why Digital-Twin Scale Came To Be Driven By GCCs

Strategically Valuable Use Cases

Strategic Impact

Business Outcome

Legacy Reality

GCC-Led Digital Twin Reality

CAPEX decision certainty

Pilot data + gut

Full-scenario exercises; investment confidence.

Asset downtime

Reactive maintenance

Predictive maintenance: 25-55 per cent reduced maintenance cost

Time-to-market

Serial engineering

Parallel virtual testing: up to 50% faster NPI

Global rollouts

Local rework

GCC’s templates and playbooks that could be reused.

Economic Benefits

GCCs as Virtual Decision Governments

frequently asked questions (FAQs)

Aditi

Hey, like this? Why not share it with a buddy?

Related Posts

Recent Blog / Post

- Pharma GCC Setup Services in India: Strategic Considerations for CXOs January 9, 2026

- Why Enterprises Are Rethinking Their GCC Strategies in 2026 January 8, 2026

- Why Most Enterprise Expansion Strategies Fall Short of Projections, And How a GCC Enabler Can Bridge the Gap January 7, 2026

- India’s GCC Ecosystem: Why the World’s Biggest Companies Are Betting Their Future on it January 3, 2026

- Healthcare GCCs in India: Where the World’s Pharmaceutical Innovation Actually Happens January 2, 2026

- Circular Economy Models and Their Relevance to Manufacturing GCCs December 30, 2025

- GCCs in Agritech: Digitizing Global Food Security December 29, 2025

- Renewable Energy GCCs: Accelerating Global Green-Tech Development December 29, 2025

- Cyber Resilience 2030: Multi-Layer Security Architecture for GCCs December 26, 2025

- Building an Integrated Risk Management Framework for Multi-Region GCCs December 26, 2025

- The Ethics of Automation: How GCCs Maintain Human Oversight in AI Workflows December 25, 2025

- Future of HR in GCCs: Data-Led, Skills-Based, and GenAI-Driven December 25, 2025

- The Proposal to Standardize India’s GCCs for Unshakeable Global Leadership December 24, 2025

- Global Capability Centers: A Strategic Growth Model for B2B Enterprises December 24, 2025

- AI Ethics & Compliance Mandates for GCC Operations in 2025 December 23, 2025